Comprehensive Guide to Tricycle Rear Axle Maintenance

The rear axle of a tricycle is one of its most crucial components. It serves as the backbone of the drivetrain, transmitting power from the pedals to the wheels. The condition of the rear axle directly affects the tricycle’s stability, handling, and overall performance. Moreover, the alignment of the rear axle, or its concentricity, plays a significant role in the longevity of the bearings and smooth operation of the vehicle. Neglecting rear axle maintenance can lead to premature wear, unnecessary noise, and potential safety issues.

Rear Axle Concentricity and Bearing Life

Concentricity refers to how well the centerline of the rear axle aligns with the axis of the wheel’s rotation. When the axle is properly aligned, the load is evenly distributed across the bearings, allowing for smooth operation. However, if the axle is misaligned, even slightly, the bearings can experience uneven stress, leading to faster wear and tear.

One of the biggest factors is driving habits—especially when riding over large potholes, bumps, or other obstacles at high speeds. The sudden shock can cause the rear axle to momentarily bend, even if you can’t see it with the naked eye. This subtle deformation can shorten bearing life significantly.

The consequences of poor axle concentricity are pretty clear: first, the bearings wear out faster due to uneven pressure. As they degrade, they can make annoying grinding or squealing noises, which isn’t just unpleasant—it’s a sign that something’s off and needs attention. Over time, the stress on the bearings and axle can cause even bigger problems, damaging the drivetrain components like the wheels, chain, and gears. This can result in costly repairs and downtime.

Best Practices for Rear Axle Maintenance and Proper Driving Habits

Taking care of your rear axle starts with good riding habits. First and foremost, try to avoid high-speed impacts. Riding over big potholes or obstacles at speed can put a lot of stress on the rear axle and cause it to bend or misalign, even if you can't see it. Slow down when navigating rough terrain or any area where you know there could be a hazard.

Also, make sure you're not overloading your tricycle. Heavy loads put extra strain on the axle, speeding up wear and tear. Stick to the manufacturer’s weight limits, and always try to distribute the load evenly to keep things balanced and reduce strain on the rear axle and bearings.

Regular inspections and maintenance are key to keeping everything running smoothly. Start by checking the axle for any signs of deformation. While small misalignments aren’t always visible, look for wobbling when the wheel spins. If it’s not running true, the axle might be slightly bent. Also, listen carefully for any strange noises like grinding or feel for any resistance when you spin the rear wheel. This could indicate that the bearings are starting to wear out. Keeping the bearings lubricated and checking for smoothness will help prevent this.

Lubrication and Cleaning of the Rear Axle

When it comes to maintaining the rear axle, keeping everything clean and well-lubricated is crucial. Dirt, dust, and moisture are common culprits that cause friction and wear, shortening the lifespan of the axle and bearings. Regular cleaning and proper lubrication not only help keep things running smoothly but also reduce the risk of costly repairs down the road.

1. Regular Cleaning of the Bearings

Dirt and grime can build up in the bearings over time, which leads to friction and wear. Here’s how you can properly clean the rear axle and bearings to keep your tricycle performing at its best.

Lift the Tricycle: First, get your tricycle off the ground so that you can easily access the rear wheel and axle. A bike stand works great for this, but if you don’t have one, just prop up the tricycle with a block or support to stabilize it.

Remove the Rear Wheel: If it’s necessary for better access, take off the rear wheel. This may involve unscrewing the axle nuts or releasing the quick-release mechanism. It’ll give you a better view and reach when cleaning the axle and bearings.

Inspect for Dirt or Debris: Before you start cleaning, take a quick look at the bearings and axle for any visible dirt, debris, or rust. A soft brush (like a toothbrush) works wonders for gently brushing off loose dirt and grime without damaging the parts.

Clean with a Solvent: To really clean things up, grab a degreaser or mild solvent (rubbing alcohol works well). Dampen a clean cloth with the solvent and carefully wipe down the axle and bearings, removing built-up grease and grime. Be careful not to get too much solvent into the bearings themselves, as it can disrupt the lubricant inside.

Dry the Parts: After cleaning, use a dry cloth to wipe off any leftover solvent or water. It’s important to let everything air dry completely before reassembling to avoid moisture buildup inside the bearings.

Inspect the Bearings: Once cleaned, give the bearings a quick inspection. Spin the axle by hand to see if you can feel any roughness or hear unusual noises. If things don’t feel smooth or you hear grinding, that could indicate bearing wear, and it might be time to replace them.

2. Lubrication of the Axle and Bearings

Once everything is clean, lubrication is the next step. Proper lubrication reduces friction, helps prevent rust, and keeps the axle running smoothly. It’s essential to use the right kind of lubricant to ensure long-lasting performance.

Choose the Right Lubricant: Use high-quality grease or oil that’s designed specifically for bike or tricycle bearings. A good lubricant should be moisture-resistant, durable, and capable of handling a variety of weather conditions. It’s worth investing in a quality product to protect your rear axle.

Apply Lubricant to the Bearings:

- For grease: If you're using grease, apply a small amount directly to the bearings. You only need a thin layer, just enough to coat the bearing’s surface evenly. Don’t over-apply, as too much grease can attract dirt and cause buildup over time.

- For oil: If you prefer oil, place a few drops directly on the axle and inside the bearings. Gently rotate the axle to allow the oil to seep into the bearings for optimal lubrication.

Lubricate the Axle: Don’t forget to lubricate the axle itself. Apply a thin layer of lubricant to the axle shaft to ensure smooth rotation. This will help prevent rust and ensure that the axle moves smoothly inside the bearings.

Reassemble the Wheel: Once you've lubricated everything, carefully reassemble the rear wheel onto the axle. Make sure the axle is properly aligned and secured. If you’re unsure, double-check the alignment before tightening everything up.

Test the Movement: Before you take the tricycle out for a spin, give the wheel a quick test. Spin it by hand and check for any roughness or resistance. The wheel should spin freely with minimal effort. If there’s any resistance, you may need to clean and lubricate again.

3. Regular Maintenance Tips

Maintaining your rear axle isn’t a one-time job—it’s about consistent care to keep everything running smoothly.

Inspect Regularly: Even if your tricycle seems to be working perfectly, it’s a good idea to check the axle and bearings every couple of months. Look for any signs of wear, dirt buildup, or other issues before they turn into bigger problems.

Avoid Over-Lubrication: It’s tempting to add a lot of grease or oil, but too much lubricant can cause dust and dirt to stick, leading to further issues. Just apply enough to coat the moving parts without overdoing it.

Keep It Dry: After cleaning and lubricating, make sure to wipe away any excess lubricant, especially if you plan on riding in wet or muddy conditions. Moisture can cause rust, so keeping things dry is key.

By following these simple steps, you can ensure your tricycle’s rear axle and bearings stay in top shape, giving you a smoother, quieter ride and extending the lifespan of your tricycle.

Conclusion

The rear axle is an essential part of the tricycle’s drivetrain and requires regular maintenance to ensure its longevity. By adopting good driving habits, performing periodic checks, and keeping the axle and bearings clean and properly lubricated, you can significantly extend the life of the rear axle and prevent premature bearing failure.

2 comments

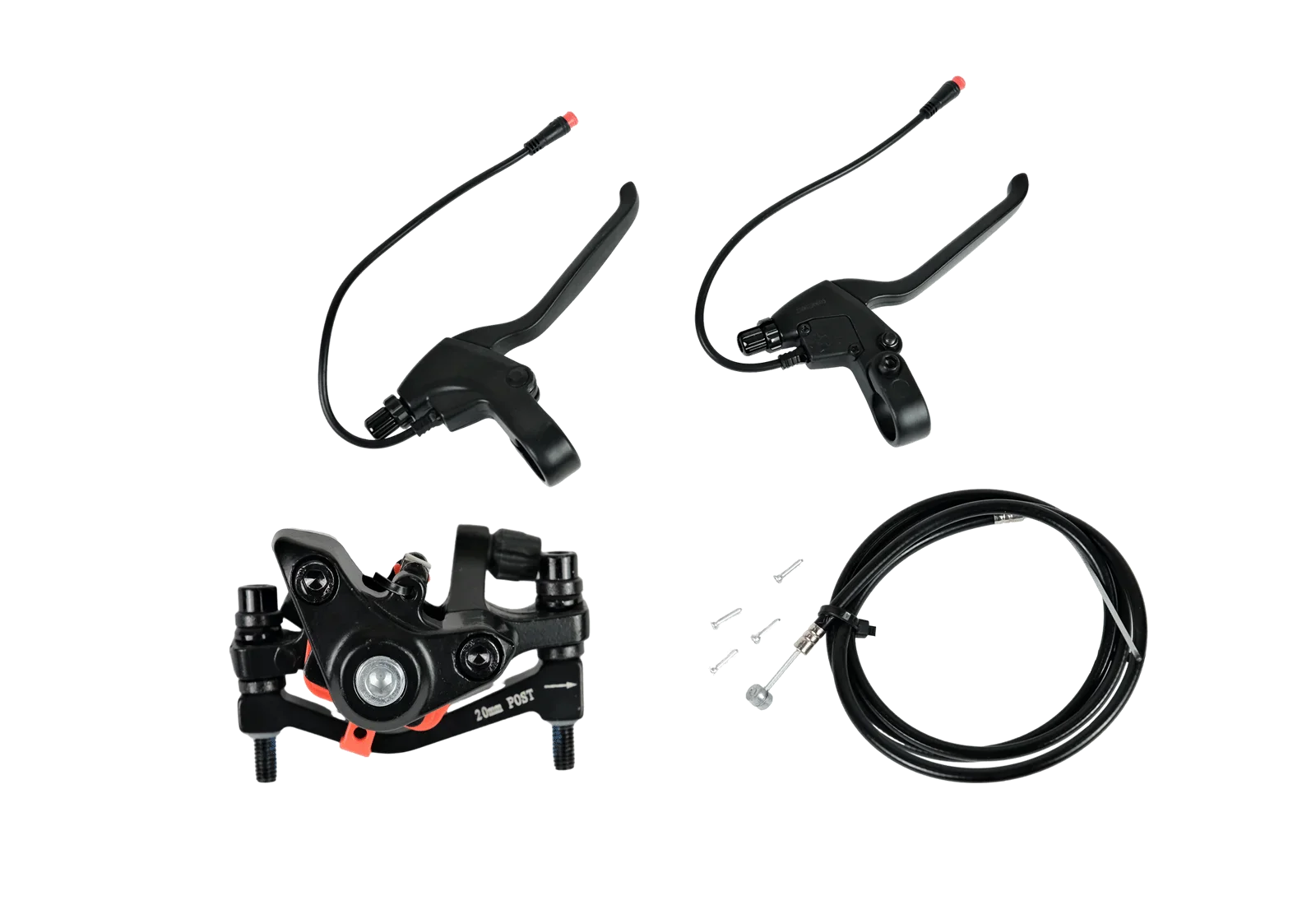

Be sure to check the tightness of the bolts that mount the calipers to the brake assembly. On just the second ride we had a caliper completely come loose rendering the rear brakes inoperative. Since the bolts were lost we could not make a field repair.

How often do the bearings need to be cleaned and lubricated ?